Heterojunction MWT solar module based on 23%-efficient cells

Scientists in the Netherlands have claimed that a heterojunction metal wrap-through solar module they are designing could offer a 4% performance improvement over conventional heterojunction panels.

The Netherlands Organisation for Applied Scientific Research (TNO) is teaming up with equipment provider Eurotron, solar project developer GroenLeven, and Dutch research institute SIEC to develop a new metal-wrap-through (MWT) solar module based on heterojunction solar cell technology.

The new “Whooper” panel has already demonstrated record efficiencies, according to its developers.

“Over 23% solar cell efficiency on six-inch silicon wafers has already been demonstrated during the proof-of-principle phase with our industrial partner CIC,” Gianluca Coletti, TNO’s program manager for tandem PV technology and applications, told pv magazine. “The concept has been further proven using other partners’ heterojunction pilot lines.”

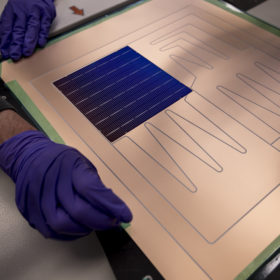

The research team explained that the Whooper module integrates silicon heterojunction solar cells with back-contact foil technology into a module that is “ready for mass production.” They have also claimed that the back-contact foil technology is the most efficient and elegant solution for the interconnection of heterojunction solar cells.

“Because most of the contacts are placed on the rear, the front of the module is aesthetically much more appealing,” they explained. Compared to conventional heterojunction panels, the new modules are said to provide 4% more power yield at a 3% lower levelized cost of energy (LCOE).

TNO is in charge of the design and optimization of the Whooper cell technology, and already identified cell producers to demonstrate the feasibility of manufacturing on an industrial pilot line. The cell technology is based on six-inch monocrystalline silicon wafers and have been previously used as bottom devices for the development of four terminal tandem silicon/perovskite cells and modules.

Back-contact specialist Eurotron will be responsible for developing a full-size module stack from backsheet to glass and ensuring compatibility with its current industrial production line.

“The company will further develop the currently available stencil print technology, investigate the optimal distribution of the paste dots across the surface, and increase speed and output of solar modules up to 90 solar modules per hour,” Eurotron said.

It added that it will also manufacturer test modules in Eurolab, its laboratory for the pre-production of back-contact solar modules and R&D projects.

GroenLeven will deploy and test the Whooper solar panels at a field lab operated by the SIEC research institute, which will utilize special mounting structures resembling those of rooftop PV systems.

“This provides a safe and controlled environment to do testing and they will host knowledge dissemination meetings on site,” the researchers explained.

They are designing the module under a research project supported by the Topsector Energy subsidy program of the Dutch Ministry of Economic Affairs and Climate Policy, implemented by the Netherlands Enterprise Agency (RVO).